Filtration

Filtration is the first stage for most of our waste water and trade effluent treatment plant designs.

The process is simple but effective and can offer great benefits.

- Removal of gross debris to protect downstream equipment

- Reduction in solids content to reduce the effects of undesirable bacteriological activity within the balancing tank

- Reduction in solids content to reduce the cost of down stream equipment that is sized according to solids loading

In summary, filtration is a high performance, low cost starting point for self treatment of waste water. It may also be improved with chemically assisted filtration – this involves the flocculation of smaller particles to make larger particles for more effective separation.

With regards to filtration, there are several options:

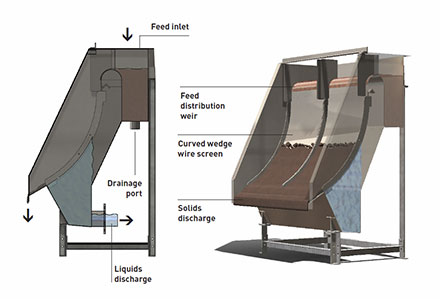

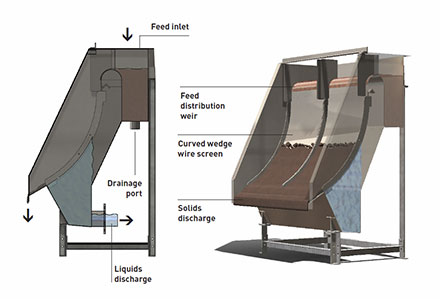

J-screen

- Allows filtration to 250 microns

- Physically strong – stainless steel wedge wire mesh, durable, long lasting

- Small footprint – 2m by 2m

- No moving parts

- Discharge under gravity

- Low cost

- Minimal maintenance

- Guaranteed to filter at 250 microns, cannot fail to work when operating correctly

- Requires periodic attention to remove built up debris/solids

- Has no effect on particles <50 microns

- Allows filtration to 250 microns

- Physically strong – stainless steel wedge wire mesh, durable, long lasting

- Small footprint – 2m by 2m

- No moving parts

- Discharge under gravity

- Low cost

- Minimal maintenance

- Guaranteed to filter at 250 microns, cannot fail to work when operating correctly

- Requires periodic attention to remove built up debris/solids

- Has no effect on particles <50 microns

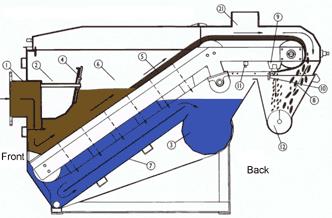

Rotary drum screen

- Allows filtration to 250 microns

- Physically strong – stainless steel wire mesh, durable, long lasting

- Small footprint – 2m by 2m

- Only one moving part – the drum screen

- Discharge under gravity

- Low cost

- Minimal maintenance

- Guaranteed to filter at 250 microns, cannot fail to work when operating correctly

- Requires mains water flush, preferably warm to hot, once per hour

- Has no effect on particles <50 microns

Salsnes

- Kevlar weave conveyor type

- Allows filtration to 200 microns or less, cloths can be manufactured at 50 microns

- Small footprint – 2m by 2m

- Only two moving parts – the cloth conveyor and screw

- Discharge under gravity

- Minimal maintenance

- Guaranteed to filter at up to 50 microns, cannot fail to work when operating correctly

- Requires mains water flush, preferably warm to hot, once per hour

- Has no effect on particles <50 microns